Aluminium Composite Panels (ACP Sheets & Boards)

Price range: $42.00 through $195.00

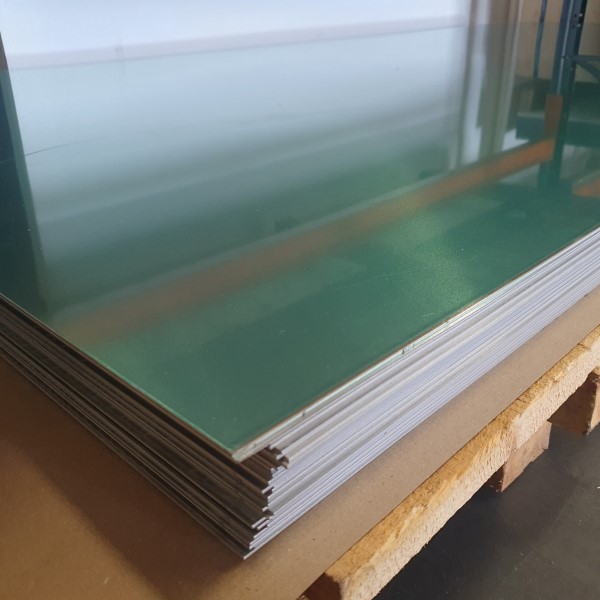

Our aluminium composite panel features a 3mm thickness and 0.21mm aluminum skin, with a lightweight polyethylene core. Ideal for signage, it is foldable and provides a modern, durable solution for various applications.

Save 10% when buying 10+ sheets

Mix & Match

Any Size, Any Colour

** Panel can be guillotine or router cut to size – just give us a call **

Aluminium composite panels (ACP) are lightweight, rigid sheets made from two aluminium layers bonded to a polyethylene or mineral-filled core. Also known as aluminium composite board or aluminium composite material, these panels are widely used for signage, displays, cladding, and architectural applications due to their strength, durability, and smooth surface finish.

Bi-Wize supplies high-quality aluminium composite panels in multiple sizes, thicknesses, and finishes. Easy to cut, route, and fabricate, ACP sheets are ideal for professional sign makers and commercial projects requiring a long-lasting and visually clean material.

Aluminium Composite Panels: Premium ACM Solutions for Australian Projects

If you’ve been in the construction industry for a while, you have likely hit that wall where a client wants something that photographs well, does not cost a lot, and will not warp in Australia after a summer or two.

Sheet aluminium costs a fortune and bends with heat. Acrylic is prone to scratching. Dibond works, but the colour range can be quite limiting.

This is where aluminium composite panels or aluminium composite boards really shine.

- The material stays flat without fussing.

- They cut clean on a CNC or guillotine.

- They survive Melbourne weather without turning into a warped mess.

.. which is more than you can say for half the materials out there.

But not every ACP is built the same. If you spec the wrong one, you’re looking at failed building inspections, panels that fade within 18 months, or worse, having to redo the entire job.

Bi-Wize is a family-owned business, backed by more than 50 years of experience in the industry. If you’re planning your next signage or construction project and want panels you don’t have to second-guess, we have got you covered.

What Is Aluminium Composite Material?

ACM is essentially a three-layer sandwich that’s been heat-bonded under pressure. Two aluminium skins on the outside (usually 0.21mm on each side) with a core material locked in between. That core is made with polyethylene if it’s a standard panel.

The aluminium skins do the heavy lifting structurally.

They let you route, drill, fold, even bend the panel without it cracking.

The core keeps everything rigid while dropping the weight to about a third of what solid aluminium would be.

This really matters when you’re hauling sheets up scaffolding or trying to fit eight panels in a ute without the suspension bottoming out.

What sets ACP sheets apart from just gluing materials together is how it’s manufactured.

The bonding happens under heat and pressure, so you’re not dealing with adhesive failure down the track. This reliability is why it is one of the most sought-after materials today. You will see it in the following use cases:

- External building cladding and architectural facades

- Monument signs, pylons, the big stuff you see from the road

- Shopfronts and retail fascias

- Feature walls and internal partitions

- Large format print substrates, when you need something flat and stable

Surface finish varies depending on what’s been ordered. It could be polyester powder coat, PVDF, brushed, or even mirror finish aluminium.

Core type affects fire compliance and weight. Skin thickness affects how cleanly it machines. All of it matters depending on what you’re building.

As one of the more established aluminium composite panel suppliers Australia trusts, Bi-Wize focuses on:

- consistent, high-quality ACP sheets

- reliable stock availability

- fast delivery across Victoria and nationwide

- and custom cut aluminium panels

Instead of trimming sheets onsite or wasting half a day resizing material, panels arrive for you, ready to install.

Types of Aluminium Composite Panels

Different jobs need different specs. Using the right type makes a big difference. This is where people commonly make mistakes.

With the wrong type of ACM, a job could get knocked back because of choosing the wrong type. You need to match the panel type to what you’re building:

Polyethylene Core Panels (PE)

This is what most sign shops keep stacked in the corner because it handles the bulk of everyday work.

Polyethylene core keeps the weight down, seamless on machines, and comes in enough stock colours that you can find something close to what you want.

Where PE is used the most:

- Shopfront signage panels and retail fascias

- Monument signs sitting at ground level

- Internal wayfinding and directional signage

- Temporary structures, hoarding, event installations

This is cheaper than FR, easier to work with, and available basically everywhere. The trade-off is fire performance. You can’t put it on a high-rise and can’t use it where codes require non-combustible materials. But it gets the job done for most.

Coloured and Specialty Finishes

Beyond your whites, silvers, blacks, there are brushed looks, mirror finishes, metallics, if you have the specific Pantone or RAL requirements.

Some finishes are shelf stock, others you are ordering in and waiting a couple of weeks for.

- Brushed hides scratches way better than gloss (good for high-traffic spots)

- Mirror looks polished

- Matte finishes photograph cleanly. This is suitable for corporate work.

Speak with one of Australia’s trusted aluminium composite panel suppliers today.

Request a quote, or place your order with Bi-Wize.