Harness the power of precision laser technology to elevate your signage projects. BI-WIZE’s advanced CO2 laser cutting service delivers unparalleled accuracy and flawless finishes across diverse materials, enabling intricate designs that traditional cutting methods simply cannot achieve. Experience the difference that 55 years of expertise makes in every cut.

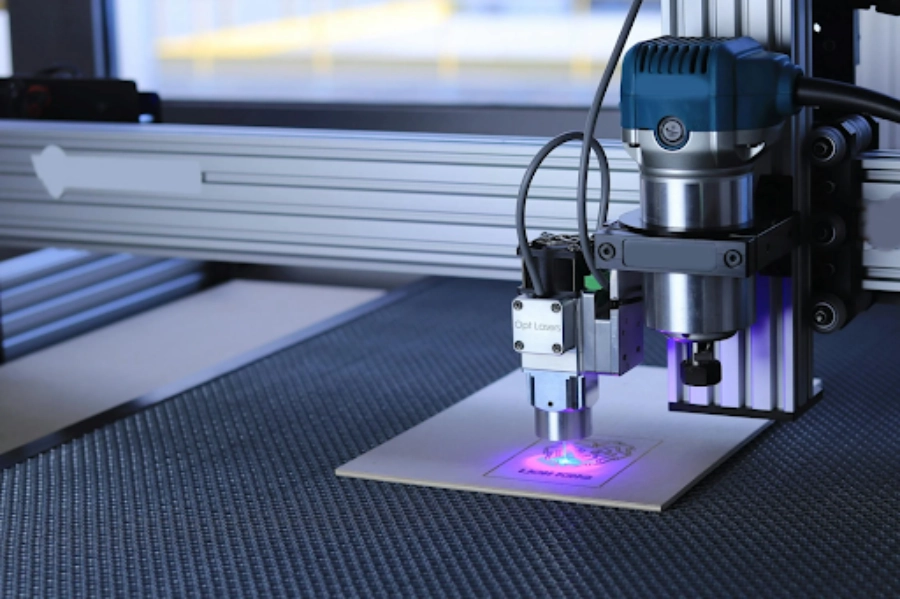

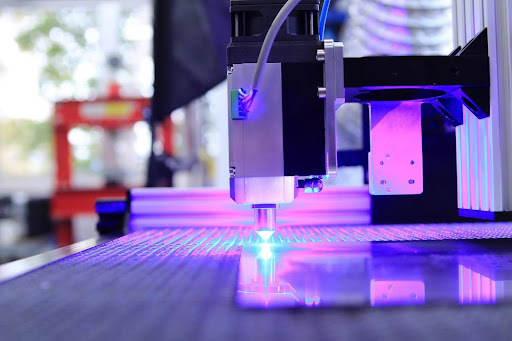

CO2 laser technology works by focusing intense heat energy directly onto materials, burning through them with remarkable accuracy. Unlike traditional cutting methods that push and pull against materials, our lasers never actually touch what they’re cutting. This means no blade dulling, no pressure marks, and the same clean results from the first cut to the thousandth. Since 1969, BI-WIZE has pioneered cutting-edge solutions for Australia’s signmaking community. Our laser cutting technology represents the culmination of decades spent understanding the exacting demands of professional signage production. From metropolitan centres in Sydney, Melbourne, Brisbane and Perth to regional workshops across the continent, our laser cutting services reach every corner of Australia’s signmaking industry. Whether working with your supplied materials or selecting from our extensive inventory, our laser cutting service accommodates unique project requirements while maintaining unwavering quality standards. Our CO2 laser technology excels across an extensive range of signmaking materials, each optimised for specific applications:

Beyond our standard inventory, we accommodate materials sourced by clients for specialised applications. Include material specifications in your project brief for accurate assessment and pricing. For metal cutting requirements including steel, aluminium, and composite panels, our precision CNC routing service delivers optimal results. Laser and routing technologies complement each other perfectly for comprehensive project solutions. Submit your design files in PDF format for comprehensive analysis. Our technicians evaluate cutting paths, material requirements, and production parameters to ensure optimal results.

Your design is translated into precise laser control instructions. Whether using customer-supplied materials or selecting from our comprehensive stock, cutting speeds and power settings are calibrated for your specific requirements.

The CO2 laser beam follows programmed paths with micrometre precision, vaporising material to create clean, burr-free edges. Automated systems maintain consistent quality throughout production.

Each component undergoes thorough inspection before careful packaging and dispatch to your location via our Australia-wide delivery network.

Our laser cutting service excels in creating:

Metal cutting utilises our CNC routing service rather than laser technology for optimal results. Metal routing costs vary significantly based on material type, thickness, and design complexity. Aluminium composite panels start at approximately $90 per project, while steel cutting requires specific assessment based on your requirements. Submit your specifications for detailed metal cutting quotes. Both technologies serve different applications and materials optimally. Laser cutting excels for plastics, acrylics, and thin materials with intricate details, while CNC routing suits thicker substrates and metals. Cost comparisons depend entirely on your specific material and design requirements. Our team recommends the most economical technology for each project during the quoting process. Laser cutting represents sophisticated technology requiring substantial equipment investment, specialised maintenance, and expert operation. However, the process delivers exceptional value through minimal material waste, eliminated secondary finishing, superior edge quality, and rapid production speeds. Many projects achieve cost savings through reduced processing steps and material efficiency compared to traditional cutting methods. Our precision laser cutting services support signmaking professionals across Melbourne’s northern suburbs and metropolitan area. Strategically located in Thomastown, we deliver exceptional results to the heart of Melbourne’s thriving signage community. Nearly six decades of Melbourne-focused expertise ensures reliable service delivery throughout:

Our Thomastown facility offers convenient collection options, with comprehensive delivery coverage ensuring consistent turnaround times across Melbourne’s diverse signmaking landscape. Transform your signage concepts into precision-cut reality through our advanced laser cutting service. Upload your design files below for comprehensive project assessment and competitive pricing. For immediate assistance, call our technical team directly on (03) 94651233 BI-WIZE – Pioneering Australian Signmaking Innovation Since 1969

Advanced Laser Technology for Exceptional Signage Results

Excellence Through Laser Cutting Technology

Thermal Precision Advantage

Proven Industry Leadership

Complete Australia Coverage

Adaptive Project Solutions

Laser-Compatible Materials Portfolio

Engineering Plastics & Acrylics

Composite & Substrate Materials

Custom Materials

Note on Metal Processing

Laser Cutting Process & Methodology

Design Assessment & Optimisation

Precision Programming & Setup

Thermal Cutting Execution

Quality Control & Finishing

Laser Cutting Applications & Capabilities

Frequently Asked Questions

How much does metal laser cutting service cost?

Is laser cutting cheaper than CNC?

Why is laser cutting so expensive?

Melbourne CNC Laser Cutting Service

Request Your Free Laser Cutting Quote

Free delivery options available!

- Home

- Shop Our Products

- Services

- Trade Printing

- Contact Us

- Cart

- Signup/Login

- Enquire Now

CNC Laser Cutting Service