Description

The Mimaki UCJV300 printer stands out with its advanced UV-LED print-and-cut technology, providing unmatched versatility and efficiency for diverse applications. Its innovative features cater to businesses looking for high-quality, durable prints with faster turnaround times.

Key Features:

- UV-LED Print Technology: Delivers instant-dry, high-quality prints with vibrant colors and sharp details, suitable for a wide range of media types.

- Print & Cut Functionality: Integrated printing and cutting capabilities streamline production, reducing the need for additional equipment and increasing workflow efficiency.

- Layer Printing: Unique 4-layer and 5-layer printing capabilities allow for creative designs such as day/night applications and transitional backlit graphics.

- Eco-Friendly: The Mimaki UCJV300 printer has UV-LED technology consumes less power and emits fewer VOCs, making it an environmentally friendly choice.

- High Precision: Ensures accurate cutting with an advanced registration mark detection system, providing precise and reliable results.

- User-Friendly Operation: Equipped with an intuitive control panel and easy-to-use software, making operation simple even for beginners.

Technical Specifications:

- Print Widths: The Mimaki UCJV300 printer is available in multiple sizes to accommodate various media widths, ensuring flexibility for different project requirements.

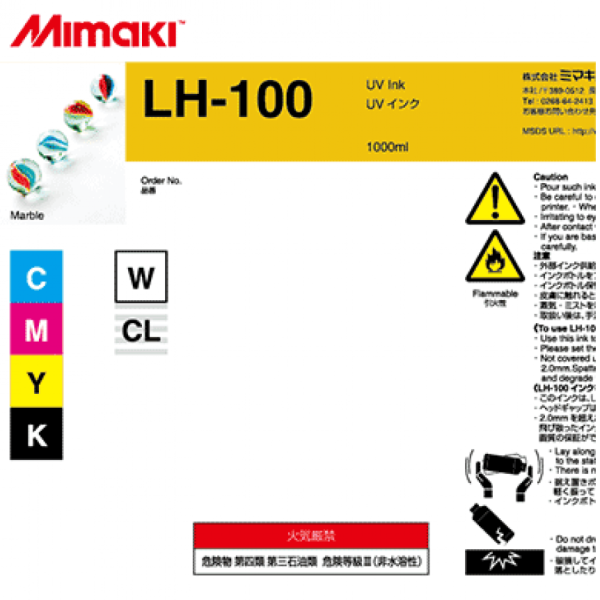

- Ink Types: Compatible with a range of UV-LED inks, including white and clear inks for special effects and high-opacity prints.

- Resolution: Capable of printing at resolutions up to 1200 dpi, delivering crisp and detailed images for professional-grade output.

- Speed: High-speed printing capabilities with a maximum speed of up to 25.8 m²/h, depending on the model and print mode.

Applications:

- Signage: Create durable outdoor and indoor signs with vibrant colors and excellent durability.

- Vehicle Graphics: Produce stunning vehicle wraps and decals with high adhesion and durability.

- Labels & Stickers: The Mimaki UCJV300 printer is perfect for producing custom labels and stickers with intricate designs and precise cuts.

- Backlit Displays: Ideal for creating dynamic backlit displays with day/night and transitional effects.

Customization Options:

- Color Choices: Supports a wide range of color options, including spot colors, white, and clear inks, allowing for highly customized and creative designs.

Dimensions:

The compact design of the UCJV300 Series ensures it fits seamlessly into various workspace sizes, with models available to match your specific needs.

Safety & Maintenance:

- Easy Maintenance: Designed for minimal maintenance, with features such as automatic cleaning and easy access to key components.

- Safety Precautions: Ensure proper ventilation and follow all safety guidelines when operating the machine to prevent exposure to harmful UV light and fumes.

The Mimaki UCJV300 Series offers a reliable and versatile solution for businesses seeking high-quality print and cut capabilities with advanced UV-LED technology. With its innovative features and user-friendly design, it is an excellent choice for professional printing needs.