Description

The world’s first model*1 of full colour printing more than 10 million colour tones

1) Applied UV curing inkjet method

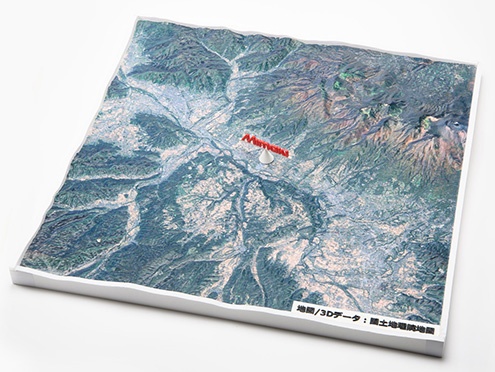

3D printer 3DUJ-553 employing the UV curing inkjet method, which performs modeling with UV ink (C, M, Y, K, White, Clear) printing, curing and piling layer by layer. Colouring is not by post processing but modeling while using colour inks, which can produce an object of exquisite full colour representation.

UV curing inkjet method (image)

Layering & colouring method (image)

Modeling by a simultaneous print with colour ink and support material ink of sliced data of a 3D object.

2) Modeling by bright colouration full colour ink

Modeling by colour ink (CMYK,White,Clear) can achieve 84% of the Fogra 39L colour gamut and cover 90% of SWOP gamut. According to modeling by colour ink with high transparency, the outside light reflects on the surface of white ink layer, which will present a good coloured modeling on the background of white layer.

3) It is the world’s first*1 technology ! Colour profile is employed to enhance the colour reproducibility

Colour profile is employed to enhance colour reproductibility.

It is the world’s first technology*1 as an inkjet method 3D printer to apply colour profile. By implementing a colour simulation profile created by [MPM3] (option) to Adobe Photoshop, the colour to be printed will be able to check on a PC monitor. The colour of object displayed on the monitor can be approached to the object itself. It is effective to reduce the working time for colour adjusting.

4) More flexible in designing with full colour ink and clear ink !

Besides transparency, clear ink can make a colour expression of translucency by the simultaneous apply of clear ink and colour ink. Clear ink gives an additional effect to show a different image when the object is lighted from its inside. The combination of clear and colour ink will broaden the design range.

Object with the clear ink (Lamp shade)

Colour ink & White ink

Without the transmission of light, the contour of object is shown clearly.

Colour ink & Clear ink

With the transmission of light, a fantastic atmosphere appears. The colour ink layer over the clear ink can create the expression of colour translucency.

Remarkable expressive power for elaborate modeling by Mimaki’s concentrated technologies

1) High accuracy of ink drop placement technology amassed in Mimaki 2D printing experience

Thanks to Mimaki original wave form control and high precision ink firing technology, amassed in the development of inkjet printer for professionals full of their strict requirements of high quality image, our 3D printer’s precise ink droplet placement has achieved as completely aimed. This high accuracy can generate an elaborate modeling focused on detailed finishing.

2) Variable dot function for less granularity modeling

Variable dot function contains sorting to fire 3 dot sizes and selects always the optimal size for modeling. This specified function enables modeling of beautiful gradation of less granularity and extremely high accurate full colour.

Excellent post process performance by availability of over coating and drilling

Acrylic resin is compounded in the ink to obtain the equivalent hardness of ABS resin, therefore over coating, drilling and attachment of screws are available.

They will give superior weather resistance and sufficient strength to maintain signs fitting with a created object, besides the brilliance of finish being adaptable to use as a final product due to the over coating.

Object with over coating

Over coating can make a smoother surface and upgrade the weather resistance.

Object with drilling

It has the strength to bear 5 kg drawing force under tight screwing.

Usability in pursuit of “easy fabrication”

1) Water soluble support material gives beautiful finishing with very simple operation.

The water soluble substance is applied for the support material utilized together for modeling. Therefore it will be washed away by soaking in water instead of scratching off.

It is convenient to be able to remove the support material of delicate designed object without damage.

Removing support material

The removing time of support material depends on size and modeling configuration.

Object after removal of support material

A space will be formed between the dragon and the ball after washing away the support material there. It will give a design option to rotate the dragon holding ball.

2) UV LED is applied as the curing light source

[3DUJ-553] applies UV ink curing by irradiation of UV (Ultra Violet). The UV LED of curing source hardly exerts thermal influence to object and start time for lighting-up is not necessary. Long life and power saving can reduce the running cost.

Secured operation support to minimize losses

1) Equipment of the ink circulation print head prevents the nozzle clogging.

The world’s first equipment*1 with the ink circulation print head as the 3D inkjet printer. Stable ink firing by the equipment of [Ink Circulation Print Head] for circulating of ink to prevent the ink pigment sedimentation. And this ink circulation system can remove air bubbles causing the nozzle clogging to keep optimizing the best condition of ink jetting.

2) [NCU (Nozzle Check Unit)] = Automatically detect and solve clogged nozzles

[NCU] as the world’s first equipment*1 to [3DUJ-553] examines automatically the nozzle status by infrared sensor. When it detects a nozzle clogging, [NCU] performs the auto-clean to eliminate it. Detection frequency can be set per modeling data or by time. It forestalls a modeling loss after occurring a nozzle clogging.

3) Inner camera to watch modeling process

[Inner camera] is mounted for 3D printer operation and modeling process check from remote area. It allows constant check to minimize the loss of print error.

*1 Survey as of August, 2017 by Mimaki Engineering

Specifications

| 3DUJ-553 | ||

|---|---|---|

| Modeling method | UV curable inkjet | |

| Available colour number | Full colour More than 10 million different colours |

|

| Print head | On-demand piezoelectric print head (8 head inline) | |

| Ink | Type/Colour | Modeling ink: MH-100 (C, M, Y, K, White, Clear) Support material ink: SW-100 |

| Tank volume | C, M, Y, K: 3L White, Clear, Support material: 5L |

|

| Supply style | C, M, Y, K: 1L bottle White, Clear, Support material: 4.8L bottle |

|

| Available modeling area (W × D × H) |

508 × 508 × 305 mm (20 × 20 × 12 in) *1 | |

| Load capacity (Weight of modeled object) |

70 kg (154.3 lb) or less *1 | |

| Minimum layer pitch | 20 μm | |

| 3D data format | STL, OBJ, VRML, PLY, 3MF | |

| Software (Standard accessories) |

Layout software [Mimaki 3D Link] | |

| Interface | Ethernet 1000BASE-TX | |

| Power supply | Single phase AC 100-120V/220-240V±10%, 50/60Hz±1Hz x3 | |

| Power consumption |

Printer | 1300 W or less |

| External PC | 300 W or less | |

| Touch panel | 30 W or less | |

| Safety standard | VCCI Class A / FCC Class A / Compliant with UL60950, ETL / CE Marking (EMC, Low Voltage Directive) / CB Report / RoHS / REACH |

|

| Installation environment | Temperature | 15 – 35 °C (59 – 95 °F) |

| Relative humidity | 35 – 60 %Rh (Non condensing) | |

| Recomended Temperature | 20 – 25 °C (68 – 77 °F) | |

| Dust | Places without mine dust (Dust amount 0.15mg/m³ or less) *2 | |

| Dimensions (W × D × H) | 2,250 × 1,500 × 1,550 mm (88.6 × 59.1 × 61.0 in) | |

| Weight | 600kg (1322.8 lb) | |

*1: including support materials

*2: 0.15mg/m³ or less…The numerical value of the dust quantity equivalent to the office specified by the Building Standards Act of Japan.

- Some of the screens and printing samples in this website are artificial renderings.

- Specifications are subject to change without notice.

- All trademarks or registered trademarks are the property of their respective owners.

- When installation and operation training etc. of products are demanded on purchasing, an extra cost would be necessary except the products cost.

- Inkjet printers print using extremely fine dots, thus colours may vary slightly following replacement of the printing heads. Also note that if using multiple printer units, colours may vary slightly among the units due to slight individual differences among the units.

3D modeling workflow

Precautions for 3D modeling

Precautions for 3D objects

- Please make sure to execute an advanced evaluation regarding the physical property (strength, weather resistance, safety etc.) for estimated applications.

- Depending on application, a post-processing might be necessary such as top coating or wiping by ethanol.

Safety notice:

You are dealing with UV light sources that may harm your health. Please follow below guidelines strictly:

- Do not look directly into the UV light source nor place your hand, or expose your skin directly to the UV light source.

- Please make sure the room is well ventilated due to smells partially accompanying with 3D modeling.

- Please use the attached goggles and globes when taking out an object or taking off support materials after modeling.

- In addition, please read the instructions and guidelines of the manual carefully and follow those.