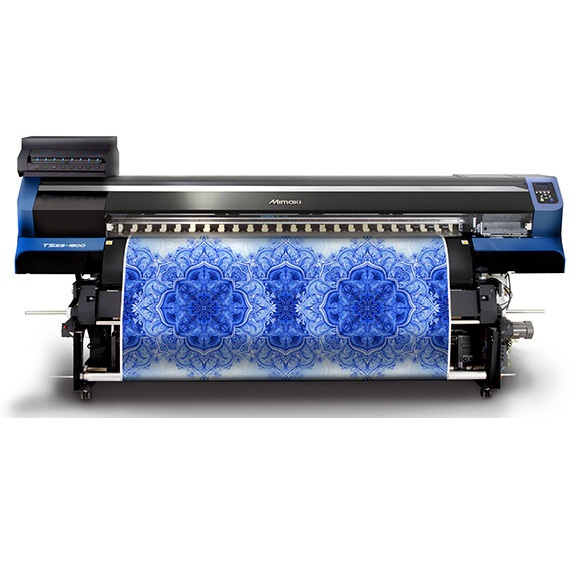

Description

Maximum output speed of 135 sqm/h (1,453 sq.ft/h)

Incorporates various print modes suitable for any work, ranging from high-speed print with a maximum rate of 135 sqm/h (1,453 sq.ft/h) to practical quality print with output speed of 50 sqm/h (538 sq.ft/h) and finally, quality-oriented enhanced picture quality print speed of 31 sqm/h (333 sq. ft/h). The practical quality mode achieves approximately 130% (*4) higher productivity in comparison with our conventional model (TS300P-1800).

* Comparison using TS55-1800:600x600dpi, 2pass and TS300P-1800:720x720dpi, 4pass, Hi (in the practical quality mode)

Option units provide for the achievement of low running cost and long-time continuous operation

Mini jumbo roll unit

This is a feeding unit to load [Mimaki Vision Jet-X] transfer paper with a length of about 2,500m (8,202 ft). Reduces the cost per square meter and shortens the downtime due to media replacement in comparison to smaller transfer paper rolls.

10kg (22 lb) ink supply unit

This is an ink supply unit to set a 10kg (22 lb) ink tank for a single colour. Compared with the conventional 2L ink pack, the running cost is much reduced and the downtime due to ink replacement is shortened.

Extended heater

This is an extended heater installed to the lower part of the standard heater. The heater enhances the ink-drying capability and prevents the “blocking” of medium (caused by still wet ink obstructing the feeding of the media during high-speed print), thus ensuring stable production.

Newly developed heads to ensure high-quality print even at high speed

“MAPS” functionality reduces banding

The “MAPS” functionality providing gradation to printed pass boundaries maintains stable print quality by reducing banding and uneven colour. The “TS55-1800” equipped with newly developed heads enables the “MAPS” in the high-speed mode, which has been unavailable so far. The technology allows the simultaneous pursuit of both high speed and high quality.

* MAPS: Mimaki Advanced Pass System

Technologies for uninterrupted reliable printing operation

NCU/NRS: Minimization of downtime

The Nozzle Check Unit (NCU) detects nonfunctioning nozzles and automatically cleans them. If the nozzles fail to operate after cleaning, defective nozzles are replaced by non-defective ones until a technician arrives, and printing is continued. This feature enables uninterrupted print operations and continuous productivity.

Nozzle recovery system by the Single-pass mode (Patent-pending) NEW!

Fill the missing nozzles by enlarging the dots of the adjacent nozzles.

* It gets missing nozzle stripes inconspicuous while printing by the Single-pass mode.

More user-friendliness!

Feed correction function by print mode NEW!

Different feed correction values can be applied to each print mode.

Feed correction value for each print mode can be managed by machine setting. It is not necessary to perform feed confirmation for every mode and reduces the work of operator.

Sophisticated “TxLink4 Lite” RIP software that has been further advanced

A 16-bit rendering realizes beautiful gradation expression.

Rendering upgraded from 8bit to 16bit enables more beautiful gradation expression. (*)

* An 8-bit rendering is used depending on the file format or colour space.

Parallel RIP and load balancing functions make production more efficient.

The RIP process for multiple pieces of print data can be performed in parallel. In addition, thanks to the load balancing function for print jobs, jobs can be assigned to printers automatically, allowing efficient production when multiple printers are connected (*).

* Additional printer licenses corresponding to the number of connected printers are required.

Parallel RIP function

RIP processes can be performed in parallel, making production that uses multiple printers efficient.

The parallel processing capability can handle up to 8 jobs.

Load balancing function

Automatically allocates* print jobs to multiple units of same printer model.

* Round robin method. Identical printers / identical ink-set printers

Variable print function tailored to applications for apparel is provided.

Variable data such as uniform numbers and player names can be directly imported from CSV file to create print jobs. Text can also be processed using methods such as text outline fills and arched text layout.

Spot colour inks (light black/fluorescent inks) that enable more beautiful and unique expression

Light black ink enables stunning grey-scale expression.

Because sublimation transfer print uses a high-density black ink, graininess or tone jump may occur in some cases. Light black ink adds to smooth print expression without graininess or tone jump.

Fluorescent inks enable unique expression.

The demand for fluorescent inks is rising in products such as uniforms and other sports apparel, fashion apparel representing Japanese cute pop culture, and eye-catching bright soft signage. To use fluorescent inks as the complementary colours of process colours, not to mention as spot colours, a multi-colour mode (*) is provided. The fluorescent inks complement magenta and yellow to realize brighter colours.

* Only available in TxLink4

Transfer paper enabling long-time continuous operation — “Mimaki Vision Jet-X”

“Mimaki Vision Jet-X” mini jumbo rolls featuring approximately 2,500 meters (8,202 ft) of transfer paper is scheduled for announcement concurrently with model “TS55-1800”.

When running the “TS55-1800” printer at its maximum speed (135 sqm/h; 1,453 sq.ft/h), a 150 meter (492 ft) roll of transfer paper runs out in approximately 2 hours. The system was therefore incapable of coping with extended continuous operation such as overnight printing in the absence of operators. The combination of “Mimaki Vision Jet-X” and the mini jumbo roll allows for unattended printing for a long time. The mini jumbo roll also contributes to reducing the running cost with lower paper costs per square meter in comparison to normal plotter rolls.

Specifications

| TS55-1800 | ||

|---|---|---|

| Printhead | Head Assy Stagger layout | |

| Print resolution | 480/600/1,200dpi | |

| Max. print width | 1,940 mm (76.4 in) | |

| Max. media width | 1,950 mm (76.8 in) | |

| Rolled media weight | 45 kg (99.2 lb) or less | |

| Ink slot No. | 8 | |

| Ink set | 4-colours / 6-colours / 7-colours / 8-colours | |

| Ink | Type/Colour | Sb610 (Bl/M/Y/K/Lbl/Lm/Lk/Fy/Fp) |

| Capacity | 2L Ink pack | |

| Certifications | VCCI Class A / FCC Class A / CE Marking (EMC, Low voltage, Machinery directive, and RoHS)/ CB Report / Energy Star / RCM / EAC |

|

| Interface | Ethernet 1000BASE-T (Recommended) / USB 2.0 Hi-speed | |

| Power | Single phase AC100 – 120V/ AC200 – 240V x1 | |

| Power consumption | (AC100V) 1.44kW or less / (AC200V) 1.92kW or less | |

| Operational environment | Temperature: 20 – 30 °C (68 – 86 °F) Humidity: 35 – 65% Rh (Non condensing) |

|

| Dimensions (W × D × H) | 3,240 x 713 x 1,857 mm (127.5 x 28.0 x 73.1 in) | |

| Weight | 202 kg (445.3 lb) | |

| Mini jumbo roll unit (Option) | ||

|---|---|---|

| Roll media size | Max. weight: Winding 100 kg (220.5 lb) / Feeding 300 kg (661.4 lb) Max. diameter: Winding 280 mm (11.0 in) / Feeding 600 mm (23.6 in) Max. width: 1,910 mm (75.1 in) / Max. printable width: 1,900 mm (74.8 in) |

|

| Power | Single phase AC200-240V x 1 | |

| Power consumption | (AC200V) 1.0kW or less | |

| Dimensions (W × D × H) | 2,773 x 998 * x 602 mm (109.2 x 39.3 x 23.7 in) | |

| Weight | 100 kg (220.5 lb) | |

* When Φ 600 roll is installed.

| 10kg ink supply unit (Option) | ||

|---|---|---|

| Ink set | 4-colours / 6-colours / 7-colours / 8-colours | |

| Ink | Type/Colour | Sb610 (Bl/M/Y/K/Lbl/Lm/Lk/Fy/Fp) |

| Capacity | 10kg (per colour) * Lk, Fy and Fp are by 2L. |

|

| Dimensions (W × D × H) | 824 x 1,035 x 383 mm (32.4 x 40.7 x 15.0 in) | |

| Weight | 35 kg (77.2 lb) | |

| Extended heater (Option) | ||

|---|---|---|

| Power | Single phase AC100-120V/AC200-240V±10% 50/60Hz ±1Hz | |

| Power consumption | (AC100V) 1.0kW or less / (AC200V) 1.0kW or less | |

| Dimensions (W × D × H) | 2,336 x 108 x 236 mm (91.9 x 4.2 x 9.2 in) | |

| Weight | 15 kg (33.1 lb) | |

Ink set

| Sb610 [Bl,M,Y,K,Lbl,Lm,Lk,Fp,Fy] |

Bl M Y K |

|---|---|

| Bl M Y K Lbl Lm | |

| Bl M Y K Lbl Lm Lk | |

| Bl M Y K Lbl Lm Fp Fy |

- Some of the samples in this website are artificial renderings.

- Specifications, design and dimensions stated in this website may be subject to change without notice (for technical improvements, etc).

- The corporate names and merchandise names written on this website are the trademark or registered trademark of the respective corporations.

- Inkjet printers print using extremely fine dots, so colours may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colours could vary slightly from one unit to other unit due to slight individual differences.